To be in line with the advance and innovation of technology in creating robots and machines that could help with almost every work that involved manpower are indeed amazing. I’m pretty sure you can now see the usage of machines and robots almost everywhere especially in most of the factories and manufacturers. This adaptation of machines and robots into this field is called a factory automation system.

It is beyond doubt how the usage of this factory automation system that would involve very little time and costs is a good thing. Either you stumbled upon this article or you are actually searching for it, it is best if you keep reading to know more.

Everything You Have To Know About The Factory Automation System

What is the meaning of factory automation system

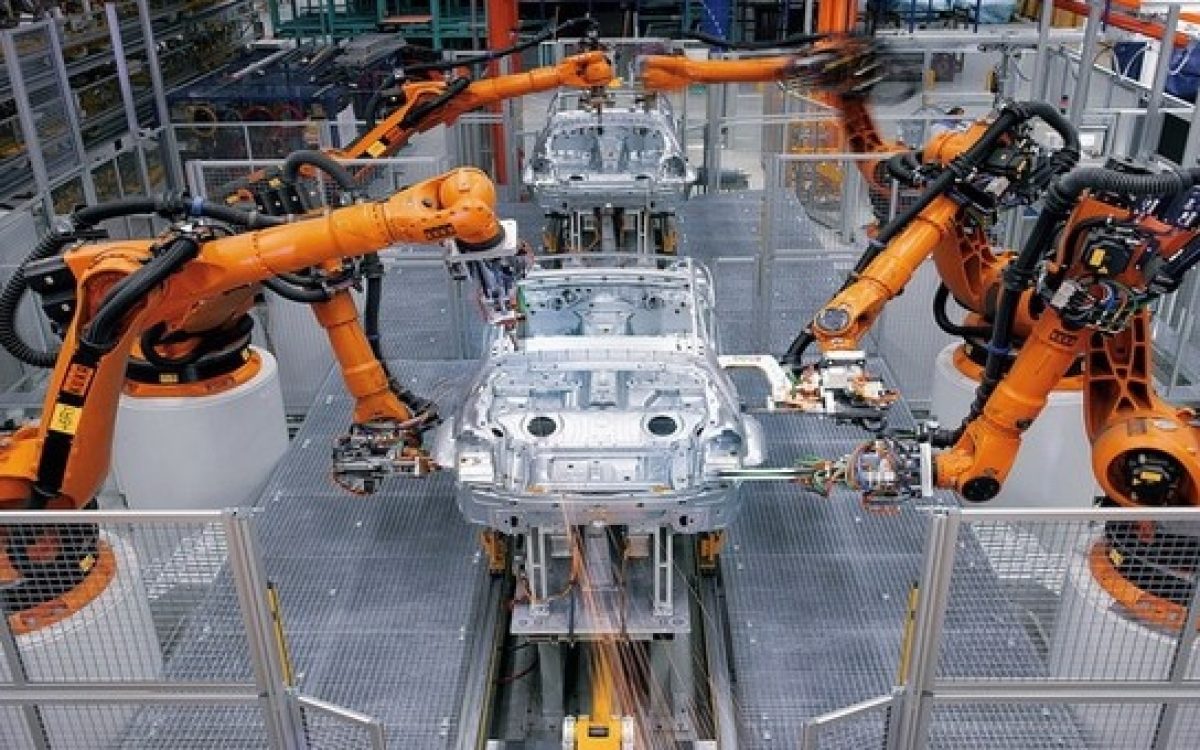

Factory automation is the use of technology and systems to automate a manufacturing process in order to boost productivity and save costs. Automation can range from a single activity to end-to-end automation with no human participation. Factory automation may be employed at each level of the manufacturing process, from material quantity management through production and assembly to packing and shipment.

The types of the factory automation system that you could get

Essentially, most manufacturers, particularly in Malaysia, adopt one of four forms of industrial automation. The types of industrial automation employed will vary based on the operations, prices, and other factors. Which includes:

- The manual or minimal automation:

This will necessitate all human labor, although there will be some automation. This may be seen in the training, expertise, and human judgment of the process.

- The single automated machine:

This machine is intended for a single, repeating usage in a specific technique. This includes a few activities like inspection and packing cutting.

- The automated production lines:

Material conveyance on a conveyor system is frequently paired with a number of specialized workstations, each of which is designed to fulfill a specific role in the manufacturing cycle. The sequence is thoroughly described, and the amount of automation determines the extent of human involvement. In a completely automated line, operators are only needed to supervise, monitor, adjust, and maintain the equipment.

- The completely automatic or (end-to-end):

The ultimate solution is a fully automated factory with no people that can run 24 hours a day, 365 days a year. These plants may possibly have self-adjustment and product quality assessment capabilities.

The pros and disadvantages of factory automation

While humans will always be the best working supply, factory automation will be the ideal technique to improve more of the manufacturers’ output. There are a few advantages to factory automation that we can see:

- The standard of living will rise.

- The consistency of the results will increase.

- Reduce your waste output.

- Can work in a more secure setting and location.

- It has the potential to save a significant amount of money.

The innovation and alternative in using the factory automation system into manufacturing factories are indeed important and beneficial to ensure the productivity and smoothen the production line.