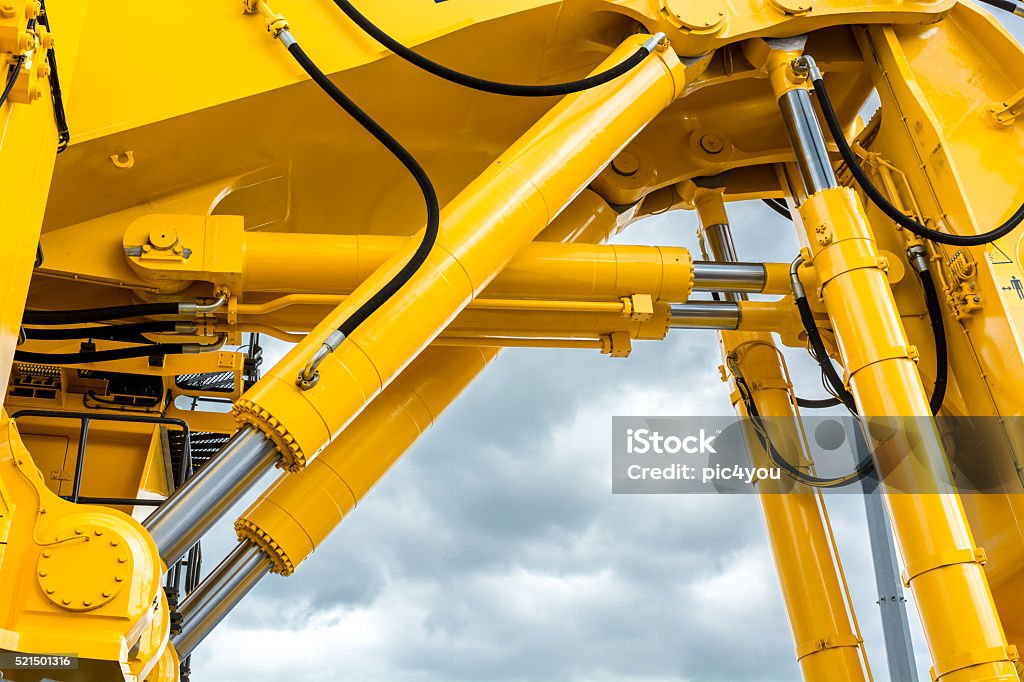

Hydraulic systems are at the heart of many machines we rely on daily—from construction equipment to manufacturing lines. Among the most essential components in these systems is the hydraulic cylinder, a device that converts fluid power into mechanical force. In Malaysia’s fast-growing industrial sector, these cylinders are indispensable across various applications.

Understanding how hydraulic cylinders work

Hydraulic cylinders use pressurised fluid—usually oil—to create linear motion. This motion powers machinery to push, pull, lift, or press with high force and precision. Whether it’s a forklift, an excavator, or a packaging machine, these cylinders are the muscle behind the motion.

Key benefits of hydraulic cylinders

Businesses sourcing hydraulic cylinder Malaysia solutions often look for performance, durability, and efficiency. These components are popular because they offer:

- High power output – Ideal for heavy-duty lifting or pressing tasks

- Smooth, controlled motion – Precise movements suited for automation systems

- Compact force delivery – Deliver significant power in tight spaces

- Durability – Built to withstand continuous use in rugged environments

Industries that rely on hydraulic cylinders

Hydraulic systems power some of the most critical machinery in Malaysia’s industrial landscape. Common sectors include:

- Construction & heavy equipment – Excavators, cranes, and loaders use hydraulic actuators for core movements

- Manufacturing & automation – Assembly lines and press machines rely on cylinders for repetitive, controlled actions

- Agriculture – Tractors and harvesters use hydraulics to operate attachments and lifting mechanisms

- Marine and offshore – Hydraulic power plays a vital role in winches, steering systems, and stabilisers

Customisation and integration

Not all cylinders are built the same. Depending on the machine or application, a business may require custom stroke lengths, mounting options, or pressure ratings. Reliable suppliers often provide technical support and mechatronic integration services to ensure the cylinder works seamlessly with sensors, valves, and electronic control units.

For companies exploring a broader set of mechatronic components—including actuators and drive systems—this catalogue outlines a diverse range of compatible industrial solutions.

The growing demand in Malaysia

The push towards Industry 4.0 and automation is increasing the demand for precision-controlled mechanical components. In this environment, finding the right hydraulic cylinder Malaysia provider can mean the difference between efficient operation and costly downtime.

Local manufacturers, OEMs, and maintenance providers are prioritising quality and service when selecting partners. Robust supply chains, reliable after-sales support, and product adaptability are key differentiators in the Malaysian market.

Whether for factory automation or field equipment, hydraulic cylinders remain essential to powering progress. As industries continue to modernise, these components will play an even greater role in shaping the future of Malaysia’s industrial economy.